An exceptional work ethic and commitment to excellence took Mayo-man Patrick Goldrick to the top of the Hardware business in the UK and South Africa. On two continents over five decades, Goldrick was instrumental in transforming the sector. Jim Copeland sat down (virtually!) with now retired Patrick Goldrick, who described from his home in South Africa a career so extraordinary, that THJ has dedicated two special features to do it justice.

Part Two: Creating a major South African retail brand.

Having reached MD of Distribution at Wickes UK, Pat was eager for a fresh challenge. But he never expected it to come from 6000 miles away!

You got the opportunity to go to Cape Town.

That was unbelievable. The organisation, Pepkor, had different brands trading throughout Southern Africa; in food Shoprite, in clothes Pep, and had recently acquired building materials wholesaler Cashbuild.

Pepkor had a vision to be the company which would feed, clothe and house the people of Southern Africa and in time, throughout Africa.

Pepkor wanted to transform Cashbuild from a wholesaler of building materials in the rural areas into a retail organisation. I had spent all my life in retail and worked successfully in the distribution side too at Wickes. When I got headhunted, I didn’t hesitate to fly out.

I’d never dreamt of going to South Africa. I left a scorching London in June 1996, and was surprised to arrive to thunder, lightning and heavy rain in Cape Town. It was their dark, wet, chilly winter.

After a few days in Cape Town, I toured the country, exploring stores in rural areas. I also spent time in Johannesburg, which had completely different weather. No rain, 25 degrees during the day but cold at night, so everything was dusty and dry.

The stores were an eyeopener. Some didn’t even have toilets, while others had steel windows hanging on trees being used as display racks!

I fell in love with the people and the country. I said yes, I’ll come and take the job. I took over the position as Managing Director in August 1996. My wife and two youngest children followed in September. That’s where I stayed until I retired in 2012.

How did you achieve the Cashbuild transformation?

My role at Cashbuild involved a hell of a lot of responsibility. I was tasked with upgrading the stores from, in some cases, literally cowsheds, and converting the wholesale business into retailers.

There were many challenges getting all the stores to a proper standard. From no concrete floors and roofs that leaked, to premises lacking facilities that enabled forklifts to work in very humid and challenging conditions.

At the same time, we needed to build a brand that was affordable and create a store footprint that suited the business. Winning staff confidence, training them and setting standards were fundamental priorities.

In the UK, I had worked with the distribution company, TNT, who used ISO 9001 for their quality standard. Because I knew how these benchmarks worked, I wanted to put something similar in place for Cashbuild.

All the stores were doing different things and following different protocols. They meant well, but I needed to control quality, so we created our own ISO 9001, ‘The Cashbuild Way’.

We didn’t want to frighten people and wanted something that was our own; that our staff could buy into as a company.

The Cashbuild Way was rolled out across the entire organisation. However, we went about it differently. For example, we got all the cashiers to tell us how they operated, how they cashed up at night, etc. Then we introduced the best practice in one store, then another, and finally in all the stores in all the regions, then the neighbouring countries.

We did the same with forklift drivers. We looked at their maintenance routines, then took the best practices to apply to every store in the company.

We also consulted with staff from the customer perspective, asking how they could deliver the best service, working backwards to the beginning of the customer journey.

All the data was collected and analysed. That became the process and the basis for our training.

We then created champions for each of the processes, which would change and adapt over time. It was always a dynamic system and still evolves today. Staff can input into it; constant development, adaptation and improvement is at the heart of The Cashbuild Way.

What was your vision for supplier relationships?

One of the most important things we did was to look after our suppliers. I didn`t want to be adversarial, so we sat down and agreed terms.

If we promised to pay in 30 days, then we paid in 30 days. If suppliers said they would deliver a product on time, we held them to that or they paid an equivalent to the margin lost due to the late delivery.

We typically gave our suppliers a three-month hard forecast of what we required in advance. A month beforehand, we worked with them on the actual breakdown.

We guaranteed to take between 95% and 110% of our forecast on a call-down basis and agreed to pay for it all within terms once they met the delivery times.

By being straightforward and transparent, we gave suppliers an insight into how we did business and that gave them confidence in us. My mantra was “better on Cashbuild’s shelves and exposed to customers than hidden in your warehouse”.

All products in the business were, and still are today, associated with other products. If you’re selling wood, you need a hammer and nails.

When I joined Cashbuild, we only had one supplier of most products including paint and nails. It was vital that the whole range was available to customers.

In 2001, we sold 20% of South Africa’s bagged cement and one million litres of paint per week. That puts into perspective the volumes we were dealing with on very low margins of around 19%.

Training and education is important to you.

Very. I left school at age 13 and all my training happened in the workplace with great mentors. It has always mattered a lot.

Staff development was another key area for Cashbuild. To expand, we needed staff with skills, especially at store management level. It was not possible to bring in people at operational level from FMCG or the clothing sector, because what we did and sold was very different.

When people joined us at entry level, we trained them to be the best they could be at that job and gave them responsibility. They got to understand the products and how and when they were purchased. We also taught our employees to drive a forklift truck.

One major cultural difference in South Africa was that our regional geographical areas were tribal. When opening new stores, it was not possible to take staff from one tribal area to manage a store in another tribal area.

Racial diversity was very important; the store personnel had to reflect the customer base as much as possible. We promoted from within, moving individuals from entry level to management. This worked very well, especially in rural areas. Having a local former entry-level employee now as Store Manager gave us strong community support and buy-in from the catchment area. Improving the career prospects of young people from the locality was a great brand-building exercise, as well as the right thing to do.

A manager’s skillset comprised of every element of the business. Our managers had to understand the Cashbuild processes in detail.

I believe employee development is essential to a successful business. It`s not always about employing the best brains; hiring individuals who were interested in working in the company, learning, and understanding their community of customers was essential.

What other ways did Cashbuild support staff and communities?

Cashbuild was very innovative. We started Sunday trading in 2000 and had family days, but we never traded on Mother’s Day, Cashbuild employed thousands, many of them mothers, and it was important to me personally that all our employees had the opportunity to see their mothers and mothers see their children, especially on Mother’s Day.

We also never needed a union; an achievement with 6,000 employees!

We developed a community employment model around our rural stores, working with locals, they bought cement from us, then quarried sand, made blocks, and sold the blocks back to us for re-sale.

We even put glass-cutting benches into some of our car parks and yards for customers to buy large sheets of glass and cut to size for their own customers.

Local deliveries were made by residents within the area in small pickup trucks or sometimes a donkey and cart.

By the end of the 2020 financial year, 383 delivery drivers were contracted across the Group’s stores. For this service Cashbuild spent R165.8M. (€9.8M)

I am very proud of Cashbuild’s social responsibilities in supporting schools. Over the past 20 years Cashbuild has donated building materials to each school in the community where a new store opening or refurbishment took place.

Access to these materials is strictly controlled by the local Cashbuild store manager, to ensure they are used for the intended school improvement purpose. Since the inception of the programme, Cashbuild has donated materials worth R45.2 million (€2.7M) to 3,543 schools.

As the business grew stronger, we asked shareholders for 10% of their shares to create an employee trust. Twice a year the dividend is divided equally amongst all staff members irrespective of their years of service or role within the organisation.

Sharing the profits in this way remains in operation today. Since inception in 2005, the trust has distributed R271 million (€16 M).

How is retirement suiting you?

Since 2012, I’ve had no involvement in the business except for periodic chats with former colleagues, usually around the annual trading statement and accounts returns, see www.cashbuild.co.za, for further details.

I am still a shareholder and retain an interest in Cashbuild from a distance. I am enjoying my retirement travelling with Rosalind and visiting our family.

Cashbuild continues to grow profitable market share. The figures at the end of the 2020 Financial Year show revenue was R10.1 billion (€600 M), profit before tax R394 million (€23.4 M), store numbers at 318 and 6,213 employees.

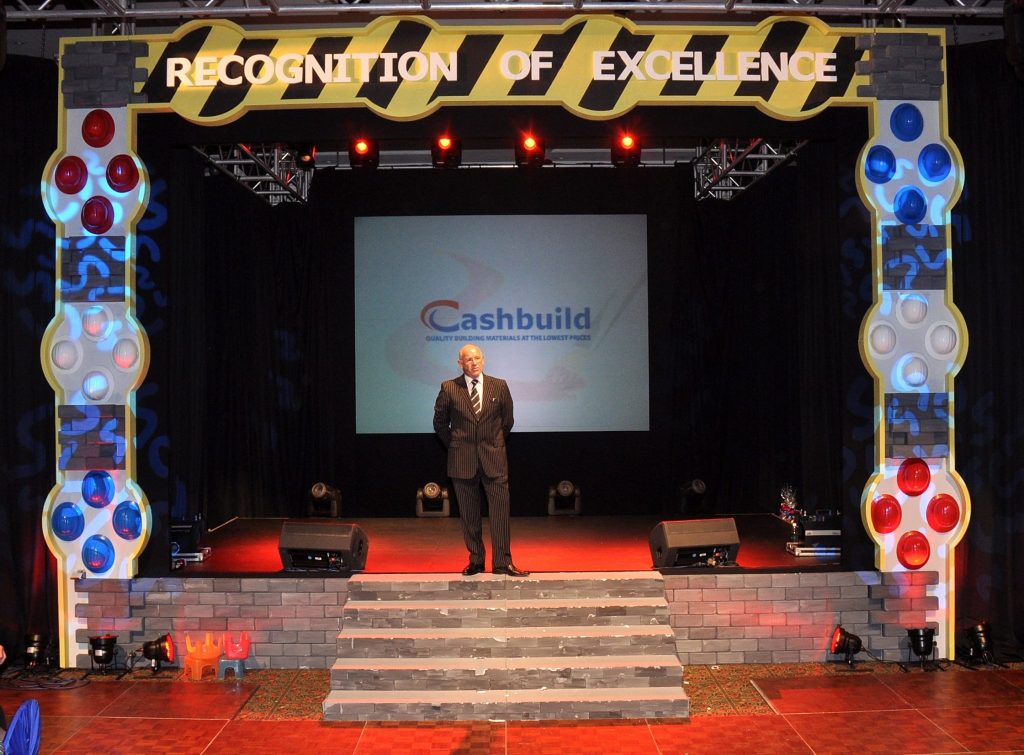

I have been very fortunate, as Cashbuild has been recognised as one of the best companies to work for in South Africa. I also had the honour of meeting great people along the way, including sharing a stage with the late President Mandela, when sponsoring a school in Soweto.

Also, many other wonderful people when opening stores and sponsoring schools.

My hardware career went from Joseph Murphy’s in Ballina in 1962 to 50 years of hard but enjoyable labour, including 16 years in South Africa.

I still think back to my early years and first mentors, Peter Laing and Gerry Connor, who set me on the right road in the trade we all enjoy today. The lessons they taught have stuck with me throughout and have been key to my success. I always set out to do a good job. Once you do that you are rewarded and can “come to work on Monday”.

What advice would you give to those joining the sector or already established within the sector?

You need to grasp each opportunity and stage in life with both hands. During my career I always wanted to show that it wasn`t what you said, or your educational results, or who you knew; it was what you demonstrated and achieved.

You need drive, initiative and determination to do the job properly. It also is vital to be trusted by your colleagues and have integrity in your dealings with your customers and suppliers, especially in a retail business. This is the advice I pass on to anyone entering or wanting to move up in this sector.