This is my first article for The Hardware Journal and I’m excited to be a small part of this fine publication. I live and work in the United States (outside of Boston, Massachusetts). While I don’t claim to know a lot about residential and light-commercial construction in Ireland, from what I’ve researched, I think there are similarities between the two countries. As a result, I thought I would give an overview of residential construction in the US.

The first thing I noticed is that Ireland calls wood “timber”, and the US calls it “lumber”. Also, Ireland calls structures framed with wood “timber framing”, while the US calls it “wood framing”. Just minor differences in nomenclature.

The vast majority of residential construction projects in the US are wood-framed. There are many reasons for this, including wood being widely available, therefore it is cost effective; it’s strong; it’s easy to make changes to the structure; low barriers of entry to become a framer; along with being eco-friendly and renewable.

With the introduction of engineered wood products (I-Joists, Laminated Veneer Lumber, Trusses) years ago, it’s now possible to have longer floor-joists and roof spans. This is important not only because houses in the US have gotten bigger over the past 20+ years, but also most homeowner’s want an “open concept” floor plan.

As for foundations, about two-thirds of the US have basements (cellars). The southern third of the USA are usually built on slabs, all are done with poured concrete.

The species of wood used in US framing varies by geographical region, based on availability and reduced transportation costs. The Northeast and Mid-West mostly use SPF (Spruce, Pine, or Fir), which mostly comes from Eastern & Central Canada. The Pacific Coast & Northwest mostly use Douglas-Fir, which comes from Northwest US or Western Canada. The Southern regions mostly use Southern Yellow Pine, which comes from Southern US.

Practically all framing lumber used is Kiln-Dried to a maximum 19% Moisture Content. All framing lumber has a stamp on it denoting the species, the grade, whether it’s KD, and the mill number.

Lumber used outside, or in contact with concrete, is Pressure Treated. ACQ Treatment (Alkaline Copper Quaternary), a type of water-based wood preservative product containing a soluble copper(II) complex and quaternary ammonium alkyl- or aryl-substituted compound, is popular and is greenish in color. In areas where there’s a high probability of termites (like Florida) they would use wood that is treated for climate & termites.

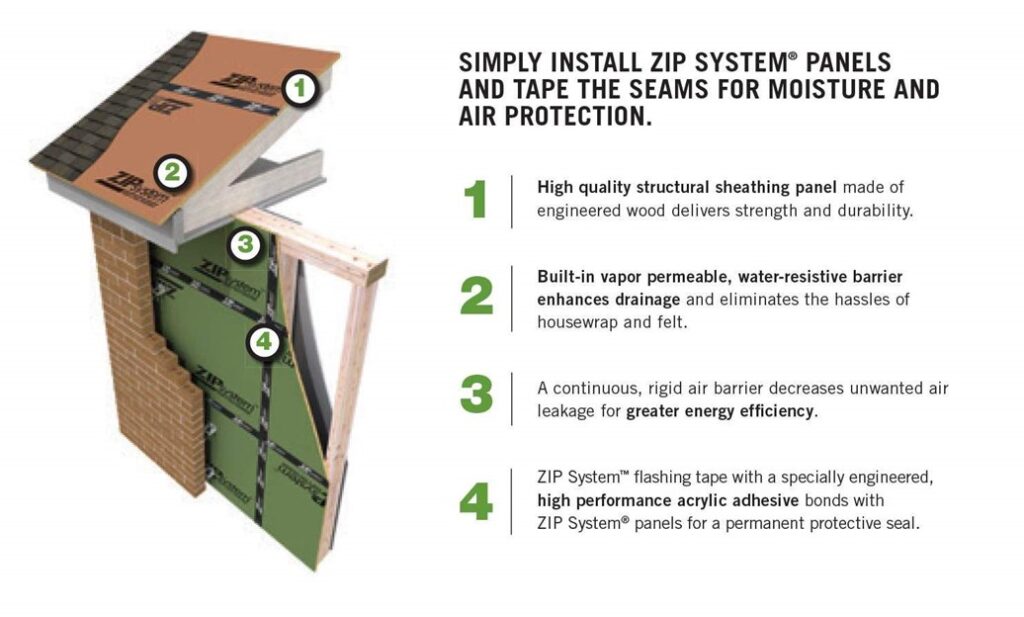

In most of the US, the exterior walls are framed with 2×6’s. This allows for more insulation to meet local energy codes, whether it be heating or air conditioning. Interior walls are usually framed with 2×4’s. Exterior structural wall sheathings are usually ½”x4’x8’ sheets, but also available in 4’x9’&10’. If plywood or OSB (Oriented Strand Board) is used for exterior sheathing, then a house-wrap would need to be applied on the outside of the sheathing and under the siding to reduce air and moisture infiltration. Roof sheathing is usually 5/8” thick and floor underlayment is usually ¾” Tongue & Groove.

There are several manufacturers who make exterior structural sheathing panels with built-in house-wrap. After installation of the panels, the seams must be sealed with a Butylene-based tape to reduce air and moisture infiltration.

Sidings vary by region and house style, but there’s no shortage of options. It seems the most popular type is vinyl siding (Polyvinyl Chloride), which can come in clapboard style; shingle style; vertical board & batten style; and in array of colors. Wood siding is used occasionally in the Northeast and Northwest when the homeowner wants the house to look “original”. But it has to be painted or stained. Fiber-Cement siding has become extremely popular over the years due to its durability, and also comes in different styles and colors. Stucco, brick and stone are used on some styles of houses throughout the US. However, they’re more popular in the South.

Exterior trim is usually dependent on the type of siding used. If vinyl siding is being used, then the trim will be vinyl. If fiber cement siding is used, then so will the trim. Wood trim is also used and depending on the region it would be either pine, cedar or redwood. Most wood trim would come pre-primed on all four sides and ready for painting. Another popular exterior trim is PVC (Polyvinyl Chloride). PVC trim does not rot and if the homeowner wants white color trim, it does not need painting. Like siding, there are many roofing options in the US. In many regions, asphalt architectural shingles are the most popular, as they are cost-effective and come with a 30–50-year limited warranty. In the mountains and northern snow regions, metal roofing is common. As for the warmer southern regions, clay tiles seem to be the norm.

Like everything else, there are many exterior door manufacturers and there is a plethora of styles. While wood exterior doors remain popular, if they’re not under an overhang, they’ll need regular re-painting. Another popular option is fiberglass insulated exterior doors. They are energy efficient, durable, and do not rot.

There is not enough room in this article to get into products like insulation, drywall/plaster, interior doors/trim/hardware, cabinetry, flooring, etc. So, I’ll have to cover the interior products another time.

My next column will be on lumberyards in the US who cater mostly to professional builders/contractors. I’ll give an overview of how they go to the market, including outside salespeople. I’ll also go over how they service their professional customers, along with what types of delivery vehicles, etc. In the US, lumberyards are large and carry practically all building materials, including hardware. However, hardware stores do not usually carry lumber, just the regular kinds of hardware, tools, paint, home gardening products etc. Feel free to reach out to me with any comments or questions.

Mike McDole has 40+ years’ experience in the Lumber & Building Materials Industry in the US and is the principal of Firing-Line LBM Advisors (outside of Boston, MA, USA). He helps dealers with management strategies, sales strategies, salespeople, gross margin improvement, profit improvement, and more. Mike can be reached at Ph. 001.774.372.1367 or Mike@FiringLineLBM.com.